Typical Applications

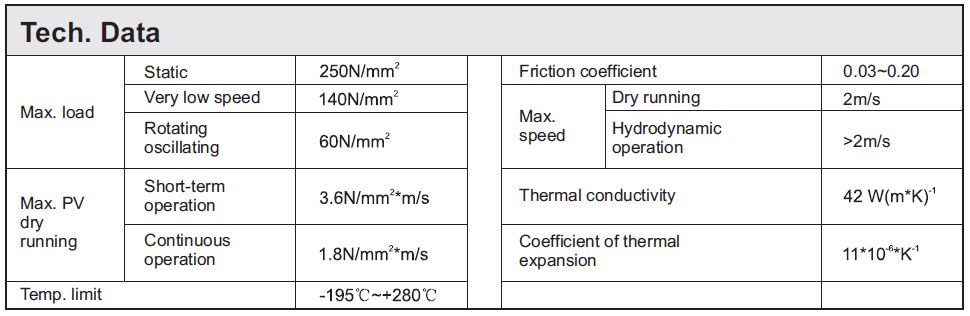

This material meets the demanding criteria for long life and trouble-free performance with or without lubrication.

- Automotive: tractors, combines, crop sprayers, earthmover, graders and other construction, auto machines, specific uses in power steering cylinders, steering gear thrust washers, disc brakes, callipers and pistons, shock absorbers, governor linkage, wind shield wiper motor, tilt gear assemblies.

- Business Machines: photocopy machines, typewriters, mail sorters, postage meter systems, computer terminal printers and peripheral equipment, automatic printing devices, mail processing machinery.

- Hydraulics and Valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions.

- Home Appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines.

- Materials Handling: Marine engine, packaging, textile equipment, tools.

Your browser does not support viewing this document. Click here to download the document.

| Product Specifications - CSB-50 | |

| File Size: | 7597 kb |

| File Type: | |