Applications

These days, the application of the lubricant free technology (air bearings, oil impregnated bearings, solid lubricated bearings, plastic bearings, etc.) is significantly expanding into many different industries.

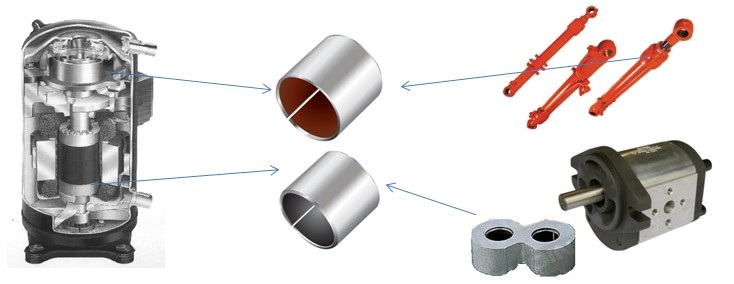

Hydraulic Components

CSB developed the bushings specially for the applications of the hydraulic components such as gear pumps, piston pumps, vane pumps, compressors and hydraulic cylinders. These metal-polymer composite bearings are most suitable for the working condition with fluid lubrication environment with high load and high operation speed.

|

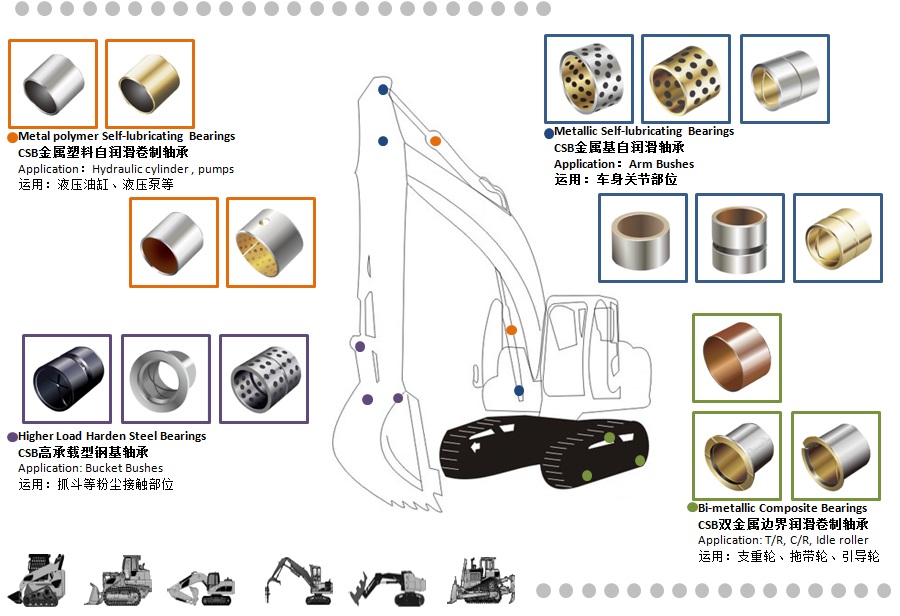

Construction Machinery

With the cooperated study and research, together with the customers, CSB has been successfully developed the most suitable bearings for the wheels, rollers, lifting arms, hydraulic cylinder bushings for the construction machineries including boundary lubricating bi-metallic bushings, metallic bushings and metal-polymer composite bushings. These bushings are made with the optimized wear resistance and dust protection features. The self-lubricating characteristics of the bearings provided considerable savings by expanded maintenance period and therefore make the machines working with higher efficiency.

|

Material Handling & Port Machiney

CSB metal-plastic composite bearing gives full play to characteristics of long service life, maintenance free, long maintenance cycle and low cost in occasions of poor environment and difficult refueling. Sealing element is suggested to be installed with the bush assembly to prevent the invasion of containments. Typical applications: Van Carrier, Stacking Machine, Lifting Platform, Port machine and so on.

|

Agricultural Machinery

The specific maintanance free characteristics of the self-lubricating bearings and the wear resistance feature when used outdoor allow the bearings to be widely applicated in the combine harvestor, planters, Strapping machines, pulverizers and tractors. The most popular components that the self-lubricating bearings could be used are the cylinders, suspension system and the connection joints where the oil or grease is hard to access.

|

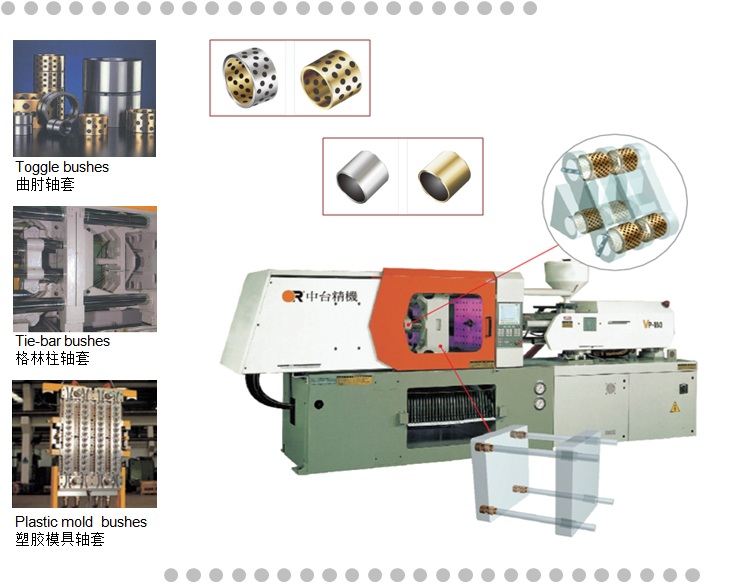

Plastic Injection Moulding Machinery

CSB first brought self-lubrication concept into plastic machinery field in China since 1995 and started to supply bushings to the world top five injection plastic machinery manufacturers with the materials including CSB-650, CSB-850 and CSB-50. The low friction, high load and long lasting features of the maintenance free bearings provided a reliable guarantee for the relative machines.

|

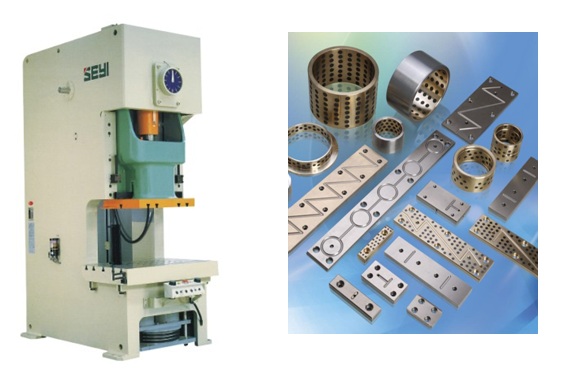

Press & Forging Machinery

CSB Self Lubricating bearing is commonly used for rotating and sliding worktable parts of machine tools, providing good guidance and maintenance-free self-lubricating operation guarantee for the machines. Its low friction and optimized performance provide a considerable cost saving and at the same time, improves the noise level of the machines during the operation.

|

Hydro Power ProjectsThis kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection moulding machines.

|