Typical Applications

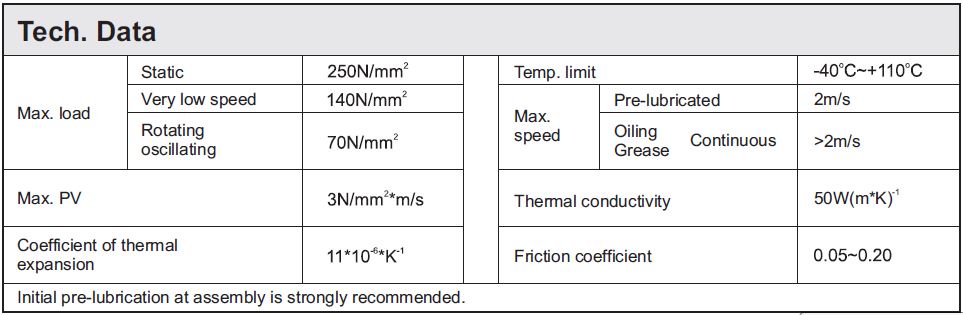

Recommended for applications involving intermittent operation or boundary lubrication.

- Automotive: suspension joints, kingpin assemblies and stub axles of tucks, auto mobile driving joint hinges, steering and other linkages, articulation joints, rear chassis hinges, fair leader rollers.

- Machine tool building industry: spindles in drill, grinding, and milling machines, ram guide plates in multi-rampresses.

- Agricultural equipment: gearbox, clutch, bale trips and wheel caster swivels for bale accumulators, front axle pivot bearings, steering idler box bearings and kingpin bearings for harvesters.

Your browser does not support viewing this document. Click here to download the document.

| Product Specification | |

| File Size: | 7029 kb |

| File Type: | |