CSB-80Features

|

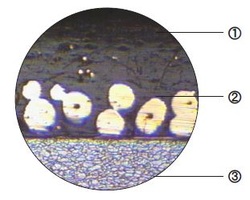

Structure

1. PTFE 0.30~0.50 mm, gives high wear resistance and low friction even only minute quantities of lubricant are supplied. This bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2.Bronze layer 0.20~0.35 mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE/PEEK mixture. 3 . Steel-backing, provides mechanical strength and high load carrying capacity. 4 . Copper/Tin plating 0.002 mm, provides good corrosion resistance. Available

|

Typical Applications

CSB-80 bearings application covered gear pump, ABS system, piston pump, gear motor, machine tools, agricultural machinery and so on. The materials is recommended with initial pre-lubrication at assembly.

| Product Specification | |

| File Size: | 2001 kb |

| File Type: | |