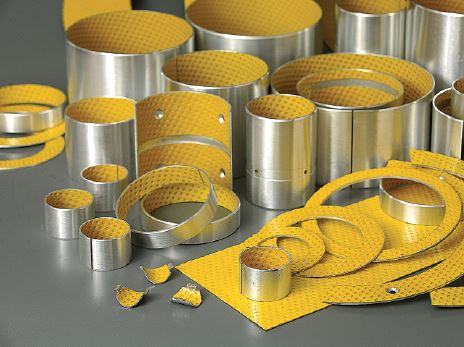

CSB - 11Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surface, suitable for rotary and oscillating movement. Very high chemical resistance, low absorption of water and swelling, also performs very good lubrication feature, the bronze backing provides the improved corrosion resistance comparing with CSB-50.

|

CSB - 20Suitable for rotating and oscillating movement, less maintenance requirements due to the long re-lubrication

intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviours, good resistance to shock loads. |

CSB - 40Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surfaces, suitable for rotating and oscillating movement, high chemical

resistance, low absorption of water and swelling. The CSB-40 improved the friction and much good wear resistance over the common CSB-50 range under lubricated operation. |

CSB - 50Suitable for dry running with a low coefficient of friction, low wear rate, good sliding characteristics, the transfer

film created will protect the mating metal surface. Suitable for rotary and oscillating movement, high chemical resistance, lower absorption of water and reduced swelling. Also performs well with lubrication. |

CSB - 80CSB-80 bearings application covered gear pump, ABS system, piston pump, gear motor, machine tools, agricultural machinery and so on. The materials is recommended with initial pre-lubrication at assembly.

|